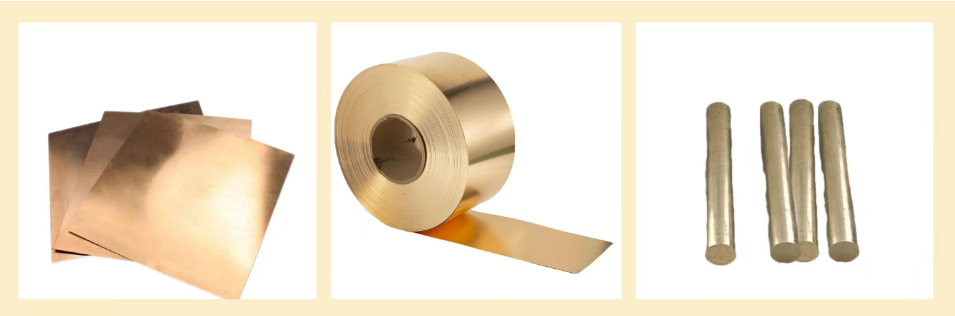

કાંસ્ય એ તાંબુ અને ઝીંક અને નિકલ સિવાયના અન્ય તત્વોનો મિશ્ર ધાતુ છે, જેમાં મુખ્યત્વે શામેલ છેટીન બ્રોન્ઝ,એલ્યુમિનિયમ બ્રોન્ઝ,બેરિલિયમ બ્રોન્ઝઅને તેથી વધુ.

ટીન બ્રોન્ઝ

તાંબા આધારિત મિશ્રધાતુ જેમાં ટીન મુખ્ય મિશ્રધાતુ તત્વ હોય છે તેને ટીન બ્રોન્ઝ કહેવામાં આવે છે.ટીન બ્રોન્ઝઔદ્યોગિક રીતે ઉપયોગમાં લેવાય છે, અને તેમાં ટીનનું પ્રમાણ મોટે ભાગે 3% થી 14% ની વચ્ચે હોય છે. 5% થી ઓછા ટીનનું પ્રમાણ ધરાવતું ટીન બ્રોન્ઝ ઠંડા કામ માટે યોગ્ય છે. 5% થી 7% ટીનનું પ્રમાણ ધરાવતું ટીન બ્રોન્ઝ ગરમ કામ માટે યોગ્ય છે. 10% થી વધુ ટીનનું પ્રમાણ ધરાવતું ટીન બ્રોન્ઝ કાસ્ટિંગ માટે યોગ્ય છે.

ટીન બ્રોન્ઝશિપબિલ્ડીંગ, રાસાયણિક ઉદ્યોગ, મશીનરી, ઇન્સ્ટ્રુમેન્ટેશન અને અન્ય ઉદ્યોગોમાં વ્યાપકપણે ઉપયોગમાં લેવાય છે, મુખ્યત્વે બેરિંગ્સ, બુશિંગ્સ અને અન્ય વસ્ત્રો-પ્રતિરોધક ભાગો, ઝરણા અને અન્ય સ્થિતિસ્થાપક ઘટકોના ઉત્પાદનમાં તેમજ કાટ-રોધક, કાટ નિવારણ અને તેથી વધુ માટે વપરાય છે. ચુંબકીય ભાગો.

ફોસ્ફર બ્રોન્ઝએકોસ્ટિક ગિટાર અને પિયાનોના તાર બનાવવા માટે સામાન્ય રીતે ઉપયોગમાં લેવાતો કાંસ્યનો બીજો પ્રકાર છે, અને તે ઝાંઝ, ઘંટ અને ગોંગ જેવા સંગીતનાં સાધનોના ઉત્પાદન માટે પણ યોગ્ય છે.

મુખ્ય એલોયિંગ તત્વ તરીકે એલ્યુમિનિયમ ધરાવતા કોપર-આધારિત એલોય કહેવામાં આવે છેએલ્યુમિનિયમ બ્રોન્ઝ.એલ્યુમિનિયમ બ્રોન્ઝપિત્તળ કરતાં વધુ યાંત્રિક ગુણધર્મો ધરાવે છે અનેટીન બ્રોન્ઝ.

એલ્યુમિનિયમનું પ્રમાણએલ્યુમિનિયમ બ્રોન્ઝવ્યવહારુ ઉપયોગોમાં 5% અને 12% ની વચ્ચે છે, અનેએલ્યુમિનિયમ બ્રોન્ઝ5% થી 7% એલ્યુમિનિયમ ધરાવતી સામગ્રીમાં શ્રેષ્ઠ પ્લાસ્ટિસિટી હોય છે અને તે ઠંડા કામ માટે યોગ્ય છે. જ્યારે એલ્યુમિનિયમનું પ્રમાણ 7% ~ 8% કરતા વધારે હોય છે, ત્યારે મજબૂતાઈ વધે છે, પરંતુ પ્લાસ્ટિસિટી ઝડપથી ઘટે છે, તેથી કાસ્ટિંગ સ્થિતિમાં અથવા ઉપયોગ પછી ગરમ કામ કરતી વખતે વધુ.

એલ્યુમિનિયમ બ્રોન્ઝવાતાવરણમાં, દરિયાઈ પાણી, દરિયાઈ પાણીના કાર્બોનિક એસિડ અને મોટાભાગના કાર્બનિક એસિડ પિત્તળ કરતાં અનેટીન બ્રોન્ઝવધુ વસ્ત્રો પ્રતિકાર અને કાટ પ્રતિકાર ધરાવે છે.એલ્યુમિનિયમ બ્રોન્ઝગિયર્સ, બુશિંગ્સ, કૃમિ ગિયર્સ અને અન્ય ઉચ્ચ-શક્તિવાળા વસ્ત્રો-પ્રતિરોધક ભાગો અને ઉચ્ચ કાટ-પ્રતિરોધક સ્થિતિસ્થાપક ઘટકોનું ઉત્પાદન કરી શકાય છે.

બેરિલિયમ મૂળભૂત તત્વ તરીકે ધરાવતો તાંબાનો મિશ્રધાતુ કહેવાય છેબેરિલિયમ બ્રોન્ઝ.બેરિલિયમ બ્રોન્ઝબેરિલિયમ ૧.૭% થી ૨.૫% ધરાવે છે.બેરિલિયમ બ્રોન્ઝતેમાં ઉચ્ચ સ્થિતિસ્થાપકતા અને થાક મર્યાદા, ઉત્તમ વસ્ત્રો પ્રતિકાર અને કાટ પ્રતિકાર, સારી વિદ્યુત અને થર્મલ વાહકતા, બિન-ચુંબકીય, અને ક્રિયાને આધિન હોય ત્યારે તણખા ઉત્પન્ન થતા નથી તેવા ફાયદા છે.

બેરિલિયમ બ્રોન્ઝમુખ્યત્વે ચોકસાઇ સાધનો, ઘડિયાળ ગિયર્સ, હાઇ-સ્પીડ અને હાઇ-પ્રેશર બેરિંગ્સ અને બુશિંગ્સ, વેલ્ડીંગ મશીનો માટે ઇલેક્ટ્રોડ્સ, વિસ્ફોટ-પ્રૂફ સાધનો, દરિયાઈ હોકાયંત્ર અને અન્ય મહત્વપૂર્ણ ભાગો માટે મહત્વપૂર્ણ સ્પ્રિંગ્સના ઉત્પાદનમાં વપરાય છે. બેલ બ્રોન્ઝ, અન્યકાંસ્ય મિશ્રધાતુતાંબુ અને ટીન મુખ્ય ઘટકો તરીકે હોવાથી, તે તેના ધ્વનિ ગુણધર્મો માટે જાણીતું છે અને કરતાલ અને ઘંટ જેવા સંગીતનાં સાધનોમાં સ્પષ્ટ અને મોટા અવાજો ઉત્પન્ન કરવા માટે આદર્શ છે.

પોસ્ટ સમય: માર્ચ-04-2025